We provide both core and comprehensive Aspect Reporting tailored to the unique needs of Brands, MSMEs & Factories.

We provide both core and comprehensive Aspect Reporting tailored to the unique needs of Brands, MSMEs & Factories.

We identify energy-related cost centers, implement cost-saving measures, and enhance factory productivity in the medium to long term.

Our services cover plastic waste management, water recycling, and Carbon Scoping Audits, complemented by extensive tree plantation and growth initiatives for carbon offsetting.

We facilitate increased business prospects, global readiness, and more through process efficiencies and certifications such as ISO, SA8000, EPR, GRS, SEDEX, and more.

We guide factories and MSMEs in achieving environmental compliance, enhancing their understanding of market needs, and preparing them for global markets.

Author: Sayani Chatterjee

India produces close to 6 million tonnes of groundnuts every year, contributing 13.79% to the world’s total groundnut production. Groundnut seeds contain 40%–53% oil and are the second most important oil seed after soybean. India is known to be the second largest producer of groundnuts in the world and is one of the top 3 exporters of groundnut, adding nearly 350 billion Indian rupees to the nation’s GDP.

Andhra Pradesh contributes 11.33% of the total groundnut produced in India Andhra Pradesh ranks third in India in groundnut production. Groundnut is grown on 8.7 lakh hectares in the State. Anantapur, Chittoor, Kurnool, Kadapa, Nellore, Guntur and Prakasam are some of the major groundnut-growing districts. Kurnool occupies the third position in Andhra Pradesh, producing 167,000 tonnes of groundnuts per annum. Kadhiri 1218 and K 6 are two major varieties of groundnut found in the region.

In spite of being one of the most important cash crops in India, the groundnut value chain suffers from various drawbacks. Aside from being susceptible to various pests and fungi during the pre-harvest stage, the lack of proper infrastructure with producers, traders and millers—inadequate grading, sorting, processing facilities, seasonality and obsolete techniques—adds to the market’s inefficiencies. When combined with the issues confronting smallholder farmers, the value chain gives the highest risk takers the smallest share of the pie.

To address the value chain issues, Catalyst Livelihood Venture (CLV), a Catalyst Group initiative, takes a value chain-based approach to improving the wealth and resilience of smallholder farmers across the country by facilitating market-based opportunities. CLV has been closely working with the FPCs (Farmer Producer Company) to address these challenges and build capacities in Kurnool, Andhra Pradesh. One of the objectives of CLV is to enable the FPCs to sell their produce directly to the market.

One such FPC in the Kurnool district of Andhra Pradesh was successful in selling 14 MT of groundnut for the first time and generated Rs. 10 lakh in turnover in the process. Despite several issues and challenges, the FPC achieved this feat with support from Catalyst Livelihood Venture (CLV).

In Kurnool, groundnut is grown by the majority of farmers and is expected to be harvested in the first week of October. As part of the pre-work activities for output produce sales, CLV, along with the ground team stationed in the Kurnool region, began scoping for buyers. The team was successful in scoping 15 buyers, consisting of local as well as modern and institutional buyers.

After discussions and approvals from the FPC Board of Directors, it was decided that the FPC would procure groundnuts from the farmers and sell them directly to the buyers. Accordingly, a procurement plan for groundnuts from the farmers was developed by the team. Procurement centres were selected, and equipment required during the procurement process such as moisture metres, weighing scales, etc., was arranged.

One of the significant components of the procurement plan was the arrangement of funds required for purchasing groundnut from the farmers. To meet the smallholder requirement of immediate payments, it was estimated that the FPC would need Rs. 10 lakhs for the procurement operations on the ground. The FPCs hit a significant roadblock when the bank rejected the loan application due to the unavailability of GST. FPC’s GST was cancelled by the board members as it deprived them of social entitlements.

To address the financial crisis, the FPC Board of Directors, on the advice of the CLV team, pooled money from other FPCs (promoted by Vrutti) in Kurnool. Fuzhio (one of the CLV partners) also offered to help the FPC with the loan in case the pooled money was insufficient. Before harvesting began, the FPC successfully raised approximately Rs. 9 lakhs. The ground team was successful in setting up the procurement centre at Kothaburuju village in the Dhone FPC area.

The excitement of the Kurnool ground team and CLV was heightened with the procurement of 6 quintals of groundnut in the 2nd week of October, only to be washed down with heavy rains hitting the region. The downpour continued for 15 days, pushing back the timeline of procurement and delivery of the product to the buyers. The entire operation came to a halt, leaving the farmers panic-stricken.

During the crisis, the on-the-ground team kept the lines of communication open with farmers and buyers. Continuous interactions with the stakeholders improved their trust in the FPC’s commitment to business. As the rain subsided, the team jump-started its efforts, walking into another roadblock. Untimely and heavy rains negatively affected the quality and quantity of groundnut available to the farmers, and the produce fell below the buyer’s expectations. Prices offered by the buyers for the produce fell, while the farmers expected a higher return.

The FPC was able to overcome the risks and challenges to procure and sell 14 MT of groundnut, generating a turnover of 10 lakhs and making a marginal profit. The team understood the market volatility and learned about incorporating the risks associated with output marketing. The team is now confident enough to undertake the bulk business of selling groundnuts and other products in the upcoming seasons.

Catalyst Livelihood Venture brings together CMS, Vrutti, Fuzhio and Green Foundation and currently focuses on developing the groundnut, pulse, millets, goatary and custard apple value chains. As part of this initiative, CLV has initiated its operations in 9 locations across the country and is working closely with 29 Farmer Producer Companies (FPC).

All of your hospital’s operational needs can be met in one place with Saarthi Health Innovation Platform (SHIP).

SHIP is an integrated solution that enables healthcare facilities access non-clinical services like financing, equipment & facility maintenance, medical waste management, legal and advisory services which leads to efficient cost management, clinical outcomes and ultimately enhances the quality of healthcare.

Nikhila Shastry and Sharmishtha Bose May 25, 2020 Chikkaballapur, Karnataka

Connecting farmers who had surplus produce with consumers who lacked access to vegetables and fruits, a farmer-producer company in Karnataka bridges the gap, benefiting both

Amidst uncertainties and restriction on transportation of persons and farm produce owing to COVID-19 lockdown, on the one hand farmers had surplus produce and on the other hand, consumers had zero or limited access to fresh vegetables.

This situation has been witnessed across the country for almost two months now. However, there are many ongoing efforts among farmers and their organisations that attempt to forge a partnership and bridge this gap.

Mokshagundam Vishweshwarayya Farmer Producer Company Limited (MVFPCL) is in the town of Bagepalli in Chikkaballapur district, at a distance of 100 km from Bengaluru. MVFPCL has 903 farmer-shareholders from 45 villages, comprising 587 men and 316 women.

Incorporated in 2016, MVFPCL has been involved in the marketing of agri-inputs such as fertilisers, seeds, cattle feed and organic growth promoters to the farmers by setting up farmer producer organisation (FPO) outlets in the villages.

MVFPCL has been supplying fruits and vegetables to established modern retailers and well-known e-commerce players in Bengaluru. During the lockdown, MVFPCL helped farmers and customers connect by purchasing fruits and vegetables from 40 farmers and selling 5 tonnes of produce to 200 consumers in April.

Bridging the gap

Vrutti Livelihood Impact Partners and Fuzhio, an impact product marketing firm that promotes impact products directly to customers on behalf of small farmers and vulnerable groups, helped MVFPCL develop market linkages during the lockdown.

Sale of fruits and vegetables in progress facilitated by Vrutti team members while following precautionary measures and social distancing norms (Photo courtesy: Vrutti)

The directors and CEO of MVFPCL were quick to gauge the impact of the lockdown on their farmers. They approached Vrutti for advice. Chandrashekarappa, director of Fuzhio, saw an opportunity to supply fresh fruits and vegetables to gated communities in the city.

The stakeholders met immediately and decided to procure produce from the farmers of MVFPCL. The staff of the producer company was able to leverage the Fuzhio and Vrutti teams’ extensive network among the residents of these gated communities.

Lockdown formalities

On March 30, a group comprising all the stakeholders was formed on a mobile messaging app. Fuzhio distributed a spreadsheet to residents’ associations of gated communities. Residents used the form to book orders and prepare lists of requirements for each day.

Fuzhio assessed the demand by consolidating data by location, apartment and quantity, and sent the same to the project staff of Vrutti and the staff of MVFPCL at Bagepalli. Since Vrutti staff had a presence in the field locations and a good rapport with the farmers, the operations quickly picked up.

The field team approached the local police station to get a vehicle pass; they also approached officials of the horticulture department, as their written consent was needed for MVFPCL to supply fresh fruits and vegetables to the city. Similarly, in the city, resident associations had to produce letters.

By connecting directly with consumers, the producer company helped many farmers sell their produce during the lockdown (Photo courtesy: Vrutti)

There was a significant reduction in transportation costs as MVFPCL has its own vehicle. They hired a driver and a few workers to assist during the operations. Everyone practised social distancing and wore masks and gloves during sorting, grading and delivery.

Logistic planning

The team planned the timing for collection, packaging, transportation and delivery. Fuzhio, who kept the spreadsheet open until 8.30 p.m. earlier, kept it running until 11 a.m. the next day. This meant that the produce had to be collected the same night instead of between 6 and 7 a.m. the next morning.

The team members scheduled the sorting of produce in the morning so that they could deliver the same to residents in the city between 12.30 pm and 4.30 pm every day. This not only saved considerable time and effort but also resulted in the sale of 200 kg of fruits and vegetables such as bananas, potatoes, cauliflower, onions and carrots daily.

Following this, observing the demand, MVFPCL further bought 15 types of groceries from local traders and other FPOs in Chikkaballapur so as to supply to the customers in gated communities. This resulted in the sale of 20 to 50 kg of extra groceries per day, thereby providing additional service to the consumers.

Expanding the customer base

On average, the team supplies produce to about 30 customers every day, with maximum sales of about 400 kg of produce worth Rs 30,000.

The working capital requirement for MVFPCL is Rs 30,000 per day. There was negligible wastage due to pre-booked orders. The team accepted payment through various platforms and payment interfaces.

If the customers felt that the quality of the product was not up to the mark, the farmers facilitated a replacement. Thus, MVFPCL was able to retain its existing customers and get new ones with these practices.

Improved income

Farmers’ feedback was contrary to the general perception that farmer members of MVFPCL did not make significant profit during these lockdown operations.

“Before the lockdown, I used to sell rose onions and cauliflower to local traders at a rate less than the market price. During lockdown, none of the traders came to buy the produce,” said Naresh, a farmer and shareholder of MVFPCL from Penumalai village in Bagepalli taluk.

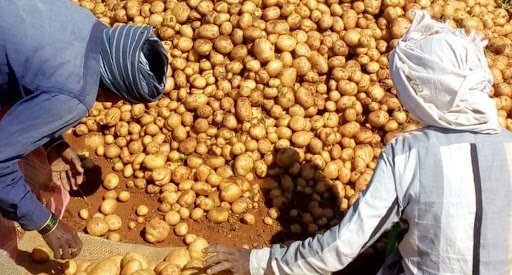

A woman farmer sorts the potato produce collected in the field based on the pre-booked orders (Photo courtesy: Vrutti)

“During the lockdown, since we have been selling directly to consumers, I could sell for Rs. 13, what I used to sell for Rs. 9 to the local trader. This shows how much higher my income has been,” said Naresh.

Business expansion opportunities

Owing to its proactive approach, MVFPCL was able to identify an opportunity in these troubled times and was quickly able to implement a farm-to-home model. Partnership with resource institutions Vrutti and Fuzhio helped the company and ensured success of the initiative.

“This is a very good initiative. Based on this experience, the farmer-producer company should explore the possibility of the B2C model as a permanent channel,” said Narasimha Murthy, head of the Business Acceleration Unit at Vrutti.

The teams of Vrutti and Fuzhio have started employing a cluster route mapping approach to tap into a number of residential areas located on the outskirts of Bengaluru, as they see huge potential in supplying fresh fruits and vegetables after the lockdown.

Even after the lockdown is lifted, this experience will help MVFPCL strategise and cater to various segments, leading to long-term relationships with urban consumers. The experience gained during this difficult phase will hold the producer company in good stead as we move into a new world filled with challenges and opportunities.

Nikhila Shastry works at Catalyst Management Services, Bengaluru. She has a master’s in Livelihoods and Social Entrepreneurship from TISS. Sharmishtha Bose works at Vrutti Livelihood Impact Partners in Bengaluru. Views are personal.

Tags: farmer producer company, lockdown

https://www.villagesquare.in/resourceful-producer-companies-address-farmers-lockdown-challenges/

Nikhila Shastry and Sharmishtha Bose Jul 10, 2020 Pudukottai, Tamil Nadu

As members struggled to buy farm inputs and sell produce, their FPCs, with special permission, arranged for inputs and sold their produce directly to consumers

In villages, the nationwide lockdown threw up many challenges for farmers and entrepreneurs. Villages in Pudukkottai district in Tamil Nadu faced similar challenges.

Farmer-producer organisations aggregate produce such as vegetables, maize, groundnuts, milk, etc., of their member farmers and sell them to maximise profit. However, the lockdown posed challenges in reaching the regular markets.

To overcome the issues, farmer-producer companies obtained special permission for transportation and took their produce for sale directly to consumers. This reduced produce waste, increased earnings for their member farmers, and provided consumers with access to vegetables and other necessities.

Sale of produce

Ambuliaaru Agriculture Producer Company Limited (APCL) in Vadakadu village, registered in March 2016, has 1,381 shareholders. Due to the lockdown, they struggled to sell their produce. While the markets were closed and farmers could not sell their produce, consumers could not buy vegetables.

Ambuliaaru APCL decided to bridge the gap. They sought permission for relaxation in vehicular movement to transport essential goods. They gained the confidence of authorities in the district administration through regular interaction. With the assurance that they would diligently follow safety norms, they obtained permission.

One of the farmer-producer companies facilitated the production of cattle feed and sold it at members’ doorsteps at a lesser price (Photo courtesy: Vrutti)

They procured brinjal, bitter gourd, okra, snake gourd, drumstick, tomatoes and other vegetables from the farmers and took them in vans to sell to individual households. If vegetables were in limited supply or not available, APCL bought them from nearby local markets and supplied them to the customers.

By approaching consumers directly, Ambuliaaru APCL sold about 7,000 kg of vegetables in a month, benefiting 1,092 farmers. From its member farmers, it also bought 15.6 tonnes of groundnut, worth Rs 7.91 lakh.

Farmers’ needs

The lockdown coincided with the sowing season for groundnut. But the input shops were closed, and the farmers could not purchase groundnut seeds. Ambuliaaru APCL made arrangements to procure 178 bags of groundnut seeds, each weighing 40 kg, from a regular supplier in a town that is more than 80 km away.

Ambuliaaru APCL not only arranged for good-quality groundnut seeds, but also supplied the same at a minimum price to its member farmers. The retail price is Rs 3,000 per bag, but the FPC supplied them for Rs 2,800 per bag. The total purchase of groundnut seeds amounted to more than Rs 5.5 lakh.

The shutdown of local shops led to a sharp increase in the price of cattle feed. Livestock farmers struggled, as the cattle feed that cost Rs 1,400 per bag of 50 kg was being sold at Rs 1,600 during the lockdown. Karambakudi Pasumai Agriculture Producer Company Limited, in Vettanviduthi village, with 583 shareholders, decided to produce cattle feed.

With the local markets closed, a farmer-producer company sold groundnuts directly to villagers (Photo courtesy: Vrutti).

As it is a mechanised process, the FPC decided to utilise the production units. They arranged for raw materials, such as black gram husk and maize, from farmers. It takes six hours to produce 1,000 kg of cattle feed and they were able to produce the required quantity.

The FPC sold the feed at Rs 1,350 per bag, Rs 50 less than the pre-lockdown market price. They also delivered the feed to the farmers’ doorsteps. In the lockdown period, until the first half of May, they did business for Rs 73,100. Apart from cattle feed, Karambakudi Pasumai APCL has also been involved in the sale of vegetables, groceries and maize.

“When most of the shops were closed and we couldn’t buy groundnut seeds, our company arranged for good-quality seeds and even delivered the seeds at our doorstep,” said Vanitha, a member of Mukkanicholai Agriculture Producer Company Limited. “It helped me sow at the right time.”

Value-added services

Members of the Ambuliaaru APCL sold groundnut oil and coconut oil, extracted in their own units, through the vans that transported vegetables. The total turnover from the sale of oils was Rs 14,307, which benefited 61 farmers.

Ambuliaaru APCL offered additional services by purchasing essentials such as spices and pulses from authorised local wholesale markets and selling them along with the vegetables. The sale of these items helped around 100 farmers make additional income.

Dairy farmers

Mukkanicholai Agriculture Producer Company Limited, in Koolayankadu village, has 790 shareholders. In this FPC, during the lockdown period, the members continued with their dairy work and distributed milk.

| During lockdown, the farmers did not hike the price of milk, as in other places. They distributed milk to households and members of the communities, besides some tea shops that were open. During lockdown, till the first half of May, the total turnover through the sale of milk was Rs 55,668, for 12 dairy farmers. |

Groundnut being sold in a wholesale shop in Vettanviduthi village (Photo courtesy: Vrutti)

MAPCL also arranged for groundnut seeds for its members. The farmers harvested paddy during the lockdown and sold a total of 343 kg of rice, resulting in business worth over Rs 20 lakh. A very important highlight across the three FPCs is the remarkable number of women shareholders—about 90% of members in each FPC are women shareholders.

Nikhila Shastry works at Catalyst Management Services in Bengaluru. She has a master’s in Livelihoods and Social Entrepreneurship from TISS. Sharmishtha Bose works at Vrutti Livelihood Impact Partners in Bengaluru. Views are personal.

Nikhila Shastry and Niraj U Joshi

Dec 8, 2021

Over the past 5 years, Mahanadi Farmer Producer Company Limited (MFPCL) has set the stage to improve tribal incomes in a remote rain-fed region where none existed for Non-Timber Forest Produce value chains like custard apple, jamun, and tamarind. MFPCL, a 517-member strong tribal farmer collective in Kanker, Chhattisgarh, has made very encouraging progress in strengthening the custard apple value chain in the remote region by developing its own pulp brand and overcoming challenges arising from the seasonality of produce coupled with the nascent enterprising skills of Tribal women.

Bastar and its natural bounty

Bastar is a richly forested landscape, with undulating hills, water streams and is a predominantly tribal area. Over 70 percent of the resident population consists of the tribes Gond, Maria, Muriya and Bhatra, among others. Tragically, though rich in beauty, natural resources and tribal culture, the forests are today dubbed “insurgency/Maoist-affected”.

There is an abundance of wild fruit-bearing trees, medicinal plants, as well as other NTFP across the forests of Bastar, including custard apple, blackberry, tamarind and mango, among others. The abundance of wild custard apples was a perfect opportunity for MFPCL to add value and convert it into a business opportunity for the members. The MFPCL is a pioneer in the custard apple value chain in the region. This first-mover advantage enabled the FPC to stay ahead of its competitors.

Formation of MFPCL through partnerships with local governments and panchayats

The local office of NABARD had approached Vrutti (NGO) for promoting FPOs in Kanker. Meanwhile, Vrutti had also been awarded a grant from the World Bank’s India office to develop a marketplace for farmers in Chhattisgarh. Thus, MFPCL was established on November 15, 2014, with an initial shareholder base of 200 farmers, which has grown to 517 farmers to date. The organisation was supported by the Business Acceleration Unit (BAU), which is a cluster-level incubator under Vrutti’s 3-Fold Programme responsible for establishing a strong ecosystem for agriculture enterprises in the region. MFPCL is involved in input business activities through Agri input facilitation centres. Each centre caters to the adjacent 2-3 villages and is run by either a women’s Self Help Group or Farmer Interest Group (FIG). MFPCL has also established forward and backward linkages for various NTFP value chains. In 2017, MFPCL was recognised as a start-up by the Department of Commerce and Industries, Chhattisgarh and in 2018, it received the best FPO Award from NABARD.

On recognising the huge potential of NTFP as an income source, albeit seasonal, Satish Mishra, the BAU Head of Vrutti, brought it to the attention of the then (2014) Kanker District Collector, Shammi Abdi. It did not take long for him to convince her of the abundant custard apple production and its high value in the market. The district administration conducted research to estimate the custard apple’s potential. The survey reported the production of at least 30000 metric tons of custard apple in Kanker district alone. To further develop this huge potential of custard apple fruit as well as its’ by-products in the market, the FPC directors, shareholders and representatives of Vrutti were then sent on an exposure visit by the district administration and District Poverty Initiatives Project (DPIP) of Udaipur, where they also got hands-on training in custard apple pulp making. In 2015, MFPCL began making pulp. The initial year saw custard apple pulp production of 165 Kg. Currently, the production cost is approximately 100 Rs per kg, for which the FPC obtains a net margin of Rs 40 for every kilogram of pulp sold.

The relations established with various government departments, including institutions such as the Agricultural Technology Management Agency (ATMA), District Mineral foundation, State Rural Livelihood Mission, with the support of BAU and Vrutti, enabled the FPC to thrive in uncertain times. Several government agricultural schemes and funds from the District Mineral Foundation (DMF) helped MFPCL in the initial phase. Local government spaces were leveraged with the support of the Gram Panchayat to establish and run procurement centres in 23 villages.

Making of the Bastar Fresh Brand

The MFPCL began its value chain development in 2016. Leveraging the existing SHGs, the MFPCL with Vrutti trained these women SHGs from 23 villages in the procurement as well as the processing of custard apples. During the Custard apple season (mid-September to December), fruit procurement, grading as well as pulp production remains an all-women activity.

A woman being trained to harvest Custard apple in Kanker

Women grading harvested wild custard apples

Women from one SHG per village pool their money to procure all the custard apples from their village, sort and grade the custard apples based on their size and other quality parameters. Superior Quality – Grade A fruits are then sold in the local and regional markets with the support of FPC. Whilst some Grade B and Grade C fruits are also sold as fruit, the rest are processed into pulp and supplied to buyers in Raipur, Indore and elsewhere. The pulp is then used to prepare custard apple milkshakes and ice cream.

Women getting ready to pack custard apple pulp in one kg packets

Initially, the pulp was branded as Kanker Valley Fresh, but as the procurement areas grew to include larger areas from other parts of the district, the branding was changed to reflect this and is now known as Bastar Fresh. The main source of income is from custard apple pulp sales, followed by jamun and mango pulp. Twelve pulp processing units were set up, of which MFPCL invested in two units and the remaining 10 were established through convergence with government schemes from the agriculture and District Mineral Foundation (DMF) funds. MFPCL’s pulp production, which began with 165 kg in 2016, now touches 10 tons annually and is growing, and the FPC is able to realise a net profit of Rs 3 lakh out of custard apple sales.

A test of resilience once support was withdrawn

The funding support from Vrutti to the MFPCL lasted for four years, after which the FPC struggled due to a lack of working capital. With insufficient funds, it became difficult to pay the salaries, thereby resulting in staff being reduced by half. MFPCL managed to raise some funds by availing working capital from nationalised banks. However, to scale its business, it currently requires a huge investment to have its own warehouse as well as a cold storage unit to preserve the fruit pulp. It also needs skilled human resources for developing business plans for the next three to five years and accessing funding support.

The pandemic severely impacted the operations of MFPCL and SHGs. The stock of almost 43 quintals of custard apple pulp from 2019-20 is lying unsold and expired in the deep freezer units with the SHGs. The SHGs could not process pulp last year as the previous year’s pulp remained unsold. With the lockdown restrictions easing in July 2021, markets have opened in Raipur and MFPCL has started procurement and processing in October with the hope of making up for the losses of the last couple of seasons as well as developing custard apple powder if funds permit. As the world is trying to regain some normalcy after the pandemic, the continuing demand for custard apples (fruit, pulp and powder) in both the domestic and international markets augurs well for organisations like MFPCL. However, MFPCL needs to constantly innovate to move forward and have contingencies built into its strategy to handle adverse situations in these uncertain times while building the necessary financial base.

Nikhila Shastry is Team Lead – Livelihood Practice at Catalyst Management Services, Bengaluru.

Niraj U Joshi is a Senior Research Associate with the Global Economic Dynamics and the Biosphere Programme, Royal Swedish Academy of Sciences, Stockholm, Sweden.